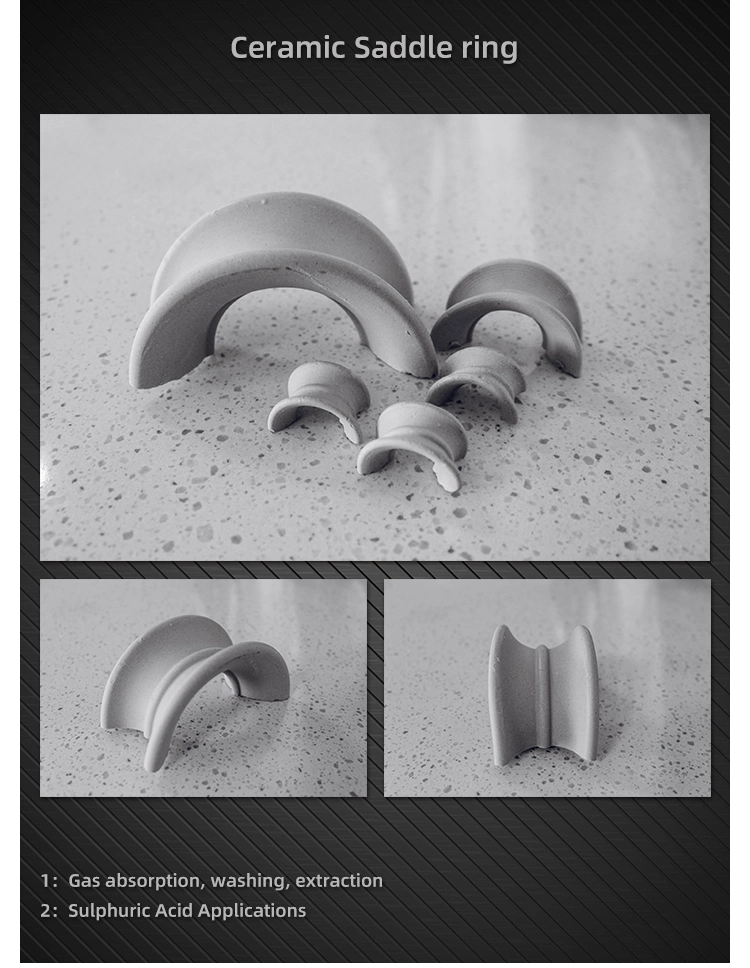

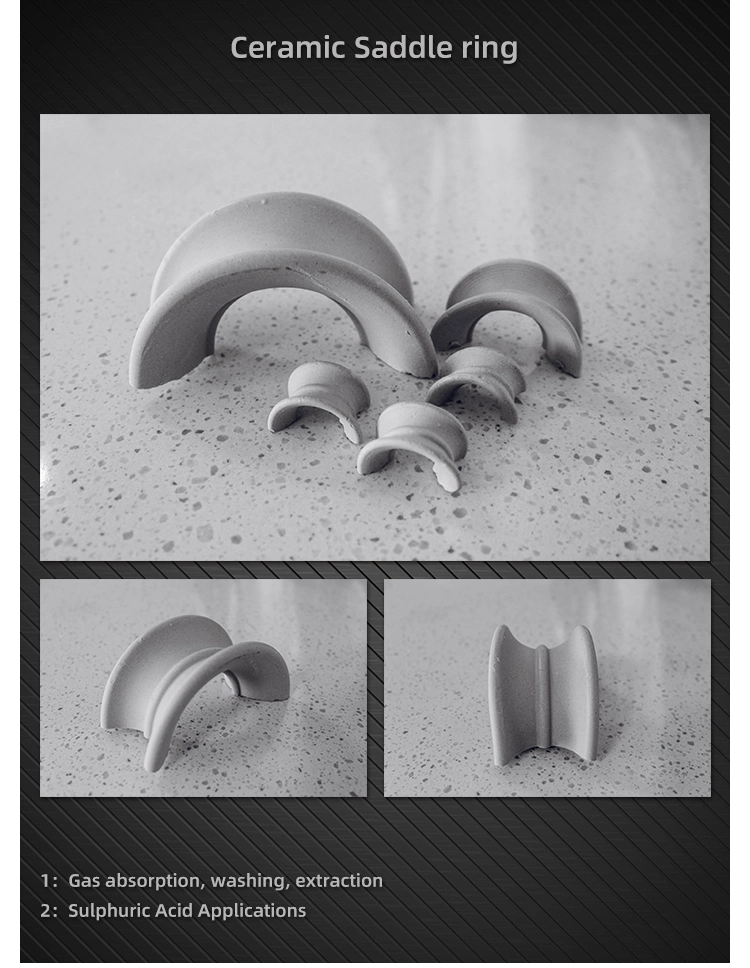

Scrubber Tower Ceramic Super Intalox Saddle Ring:

Ceramic saddles are produced in accordance with newly developed manufacturing processes. These processes ensure the production of smooth, beveled and longitudinally ribbed bodies that are consistent and uniform in shape. This eliminates fluctuations in the product performance and makes accurate predictions of operating coefficients possible. During manufacture, quality assurance testing is conducted in accordance with ASTM and DIN standards, and includes chemical analysis, maintenance of physical properties, and end-product chemical resistance.

These saddles are particularly suited for applications involving thermal shock conditions or continuous high temperature operations. The saddles are fire at 1200ºC which results in better resistance to breakage from thermal shock conditions.

Ceramic saddles are produced in accordance with newly developed manufacturing processes. These processes ensure the production of smooth, beveled and longitudinally ribbed bodies that are consistent and uniform in shape. This eliminates fluctuations in the product performance and makes accurate predictions of operating coefficients possible. During manufacture, quality assurance testing is conducted in accordance with ASTM and DIN standards, and includes chemical analysis, maintenance of physical properties, and end-product chemical resistance.

These saddles are particularly suited for applications involving thermal shock conditions or continuous high temperature operations. The saddles are fire at 1200ºC which results in better resistance to breakage from thermal shock conditions.

| Size (mm) | Specific area m2/m3 | Void rate % | Bulk number Pieces/m³ | Bulk density Kg/m³ |

| 12 | 647 | 68 | 610000 | 780 |

| 16 | 535 | 71 | 269000 | 700 |

| 19 | 350 | 75 | 146000 | 670 |

| 25 | 254 | 77 | 59000 | 630 |

| 38 | 180 | 80 | 19680 | 580 |

| 50 | 120 | 79 | 8243 | 550 |

| 76 | 81 | 75 | 2400 | 530 |